enerSENSE – Condition Monitoring

Simple digitalisation through sustainable sensor technology.

Solar-powered from the sensor to the cloud – no cables, no batteries.

More efficiency and less downtime through predictive maintenance

Sudden failures and downtimes, unscheduled maintenance work are a challenge for the maintenance team. Individual components of machines or ancillary units can lead to a complete standstill of the system.

Benefits of continuous monitoring

- Regular and continuous monitoring of machines, machine parts and processes enables you to improve your maintenance

- Early detection of impending failures

- Reduced downtime through planned maintenance

- Extension of service life through on-demand maintenance

Simple, powerful and sustainable

- Wireless retrofit solution for measuring parameters relevant to wear, such as temperature and machine vibrations.

- More data through efficient photovoltaics (enerFILM) compared to battery-powered sensors

- Sensors can be easily retrofitted at almost any point on production machines.

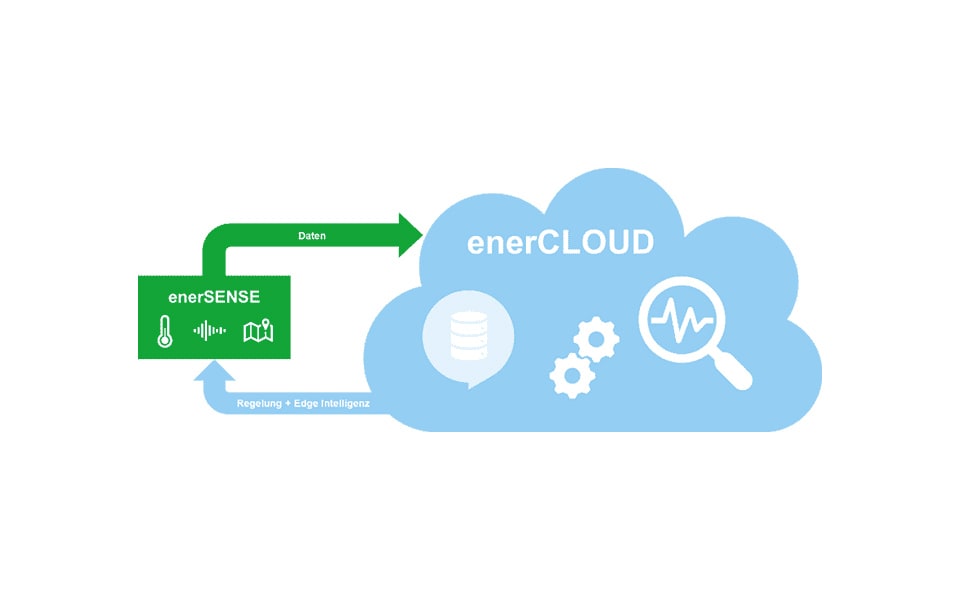

- We offer an end-to-end solution from the wireless sensors to the final measurement and analysis of results.

Smart and scalable

You keep track and stay informed

- Browser-based dashboard viewable from anywhere

- Time series representation of wear-relevant variables (vibration values and temperatures)

- Percentage change in state variables

- Notifications when limit values are exceeded or not reached (e.g. via Microsoft Teams)

- If required, the dashboards can be adapted to your individual needs.

Maximum usability of the data through cloud interface and cloud analytics

- The sensor data can be delivered to existing software solutions and partner solutions via a Cloud2Cloud interface.

- The data can be transferred via simple CSV data up to live transmission via MQTT.

- The generated vibration and temperature data form the basis for predictive maintenance.

- With the help of machine learning, anomalies can be recorded and identified and expected runtimes can be determined from them.